2 Answers

### How It Works

1. **Principle of Operation**:

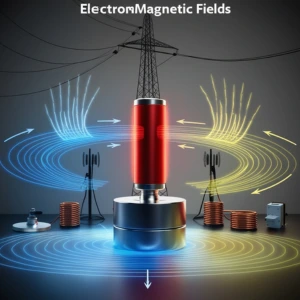

- The eddy current method is based on Faraday's law of electromagnetic induction, which states that a changing magnetic field induces an electric current in a conductor.

- An alternating current (AC) is passed through a coil, generating a magnetic field. When this coil is placed near a conductive material, it induces eddy currents within that material.

- The characteristics of these eddy currents—such as their magnitude and phase—change in response to variations in the material, such as defects or variations in thickness.

2. **Detection**:

- The eddy currents generate their own magnetic field, which interacts with the original magnetic field from the coil.

- A receiver coil measures the changes in the induced eddy currents. Any discontinuities, such as cracks, voids, or variations in conductivity, will cause alterations in the eddy current flow, which can be detected and analyzed.

### Applications

1. **Material Inspection**:

- **Crack Detection**: Eddy current testing is used to find surface and near-surface cracks in conductive materials, especially in metals used in critical applications like aircraft, bridges, and pipelines.

- **Thickness Measurement**: It can measure the thickness of non-ferrous coatings on conductive substrates, such as paint on aluminum.

2. **Conductivity Testing**:

- It assesses the electrical conductivity of metals, which can indicate heat treatment or alloying effects.

3. **Heat Exchanger Tubes**:

- The method is commonly used to inspect heat exchanger tubes for signs of wear, corrosion, or pitting.

4. **Weld Quality Inspection**:

- It evaluates the quality of welds in various industries, ensuring that there are no defects that could compromise structural integrity.

5. **Automotive Industry**:

- Eddy current testing is utilized for inspecting components such as bearings, gears, and other critical parts in vehicles.

### Advantages

- **Non-Destructive**: It does not damage the material being tested.

- **Rapid Testing**: The process can be quick, allowing for the inspection of large areas in a short time.

- **Sensitivity**: It can detect very small defects and variations in material properties.

- **Portable Equipment**: Many eddy current testing devices are portable, making them suitable for field inspections.

### Limitations

- **Conductive Materials Only**: The method is primarily effective for conductive materials, limiting its use on non-metals.

- **Surface Condition**: Surface roughness and coating can affect the accuracy of the results.

- **Depth Limitation**: Eddy current testing is mainly effective for surface and near-surface defects; it cannot detect defects deep within the material.

### Conclusion

The eddy current method is a valuable tool in non-destructive testing, offering a reliable way to detect material flaws, measure material properties, and ensure safety and reliability in various applications. Its versatility and efficiency make it an essential technique in industries where material integrity is critical.

### **How It Works:**

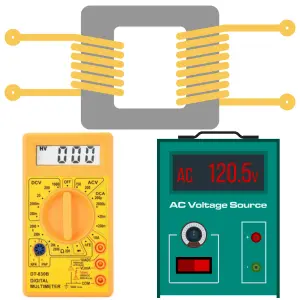

1. **Electromagnetic Induction**: When an alternating current (AC) passes through a coil, it generates a time-varying magnetic field. This changing magnetic field induces eddy currents in the conductive material being tested.

2. **Eddy Currents**: These are loops of electrical current that circulate within the material in response to the changing magnetic field. The strength and distribution of these eddy currents depend on the material’s properties and any discontinuities or defects present.

3. **Detection**: The interaction between the eddy currents and the material’s surface affects the magnetic field around the coil. This, in turn, alters the coil's impedance (resistance to the AC). By measuring these changes, one can infer the presence of defects or variations in material properties.

### **Applications:**

1. **Surface and Near-Surface Defects**: Eddy current testing is particularly effective at detecting surface cracks, corrosion, and other defects that are close to the surface of a material. It is less effective for deeper flaws.

2. **Material Characterization**: It can be used to assess material properties such as conductivity, thickness, and hardness. This is useful in quality control and ensuring that materials meet specified standards.

3. **Coating Thickness Measurement**: The method can measure the thickness of non-conductive coatings on conductive substrates, which is valuable in industries where coating thickness is critical for performance and safety.

4. **Crack Detection in Aerospace and Automotive Components**: Eddy current testing is used extensively in the aerospace and automotive industries to inspect critical components such as turbine blades, aircraft structures, and engine parts for cracks or other imperfections.

5. **Weld Inspection**: It helps in inspecting welds for discontinuities like porosity or cracks that might not be visible through visual inspection alone.

6. **Heat Treatment Verification**: The method can also verify the effectiveness of heat treatments, as it detects changes in material properties resulting from the treatment process.

### **Advantages:**

- **High Sensitivity**: Eddy current testing can detect very small surface and near-surface defects.

- **Rapid and Non-Destructive**: It provides quick results without damaging the component being tested.

- **Versatile**: Suitable for a variety of materials and geometries, including complex shapes.

### **Limitations:**

- **Surface Sensitivity**: It is less effective for detecting deeper flaws or defects well below the surface.

- **Material Conductivity**: The method requires the material to be electrically conductive, limiting its application to metals.

- **Complex Interpretation**: The data can sometimes be complex to interpret, especially in cases with irregular geometries or materials with varying properties.

In summary, the eddy current method is a valuable tool for inspecting and evaluating the integrity of conductive materials, ensuring they meet safety and quality standards in various industries.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

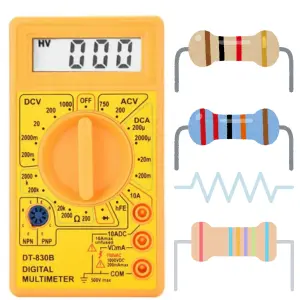

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

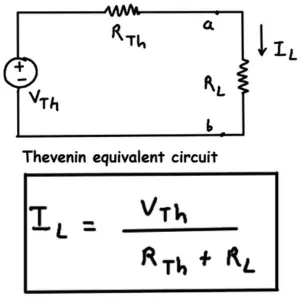

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

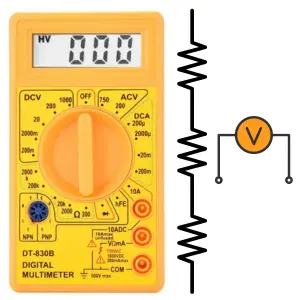

Voltmeter

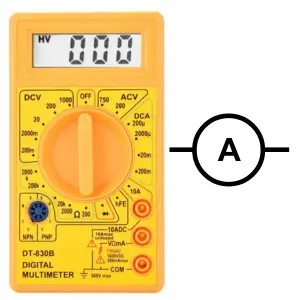

Ammeter

Induction Motor

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

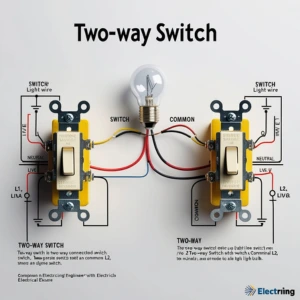

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...