2 Answers

### Advantages

1. **Induction Heating**: Eddy currents are used in induction heating, which is a process used for hardening metals and for cooking in induction cooktops. This method is highly efficient and provides precise control over the heating process.

2. **Electromagnetic Braking**: In some applications, such as trains and roller coasters, eddy currents are used for electromagnetic braking. This method provides smooth, wear-free braking.

3. **Non-Destructive Testing**: Eddy currents are used in non-destructive testing to detect cracks and defects in materials. This is a valuable method for inspecting metal parts without causing damage.

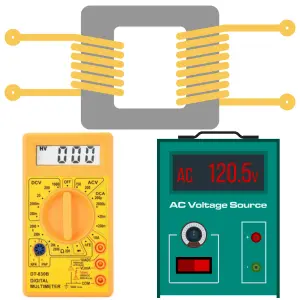

4. **Energy Efficient Transformers**: Modern transformers use laminated cores to reduce eddy currents, which improves their efficiency by minimizing energy losses.

### Disadvantages

1. **Energy Loss**: Eddy currents can lead to energy losses in electrical systems, such as in transformers and electric motors, due to the heat generated by these currents. This is why transformer cores are laminated or made from materials with low electrical conductivity.

2. **Heat Generation**: In some applications, the heat generated by eddy currents can be undesirable, such as in electrical cables and components, leading to overheating and reduced efficiency.

3. **Reduced Efficiency**: In electric motors and generators, eddy currents can reduce efficiency by creating additional losses that must be managed through design modifications.

4. **Design Complexity**: To minimize the negative effects of eddy currents, designers often need to use special materials and designs, which can increase the complexity and cost of the equipment.

In summary, while eddy currents can be harnessed for beneficial applications, they can also present challenges that need to be addressed in the design of electrical and electronic systems.

### Advantages of Eddy Currents

1. **Induction Heating:**

- **Efficiency:** Eddy currents are used in induction heating applications to rapidly heat materials, especially metals, without direct contact. This is efficient for applications such as metal hardening and melting.

- **Uniform Heating:** They can provide uniform heating throughout the material, minimizing temperature gradients.

2. **Non-Destructive Testing:**

- **Material Inspection:** Eddy current testing is a non-destructive testing method that can detect surface and near-surface flaws in conductive materials. It is widely used in the aerospace, automotive, and manufacturing industries.

3. **Electromagnetic Braking:**

- **Reduced Wear:** In trains and roller coasters, eddy currents are used in electromagnetic brakes. This system is effective for slowing down without physical contact, reducing wear and maintenance needs.

- **Smooth Operation:** Provides a smoother deceleration compared to traditional friction brakes.

4. **Energy Generation:**

- **Efficient Transformers:** In transformers, eddy currents are minimized through design (e.g., laminated cores) to reduce losses, leading to improved efficiency in energy transfer.

5. **Electrical Measurements:**

- **Measurement Devices:** Eddy currents are utilized in various electrical measurement devices, such as galvanometers and oscilloscopes, for their responsiveness to changing magnetic fields.

### Disadvantages of Eddy Currents

1. **Energy Losses:**

- **Heat Generation:** Eddy currents can lead to significant energy losses in the form of heat, particularly in transformers and inductors, where they can contribute to inefficiencies if not properly managed.

- **Reduced Efficiency:** These losses increase with the frequency of the magnetic field changes, reducing the efficiency of electrical devices.

2. **Skin Effect:**

- **Limited Penetration:** In alternating current (AC) systems, eddy currents are confined to a thin layer at the surface of conductors (known as the skin effect), which can lead to increased resistance and further energy losses.

3. **Material Limitations:**

- **Conductive Materials Required:** Eddy currents only occur in conductive materials, which limits their applicability in non-conductive materials.

4. **Inductive Heating Challenges:**

- **Control Complexity:** While induction heating is efficient, controlling the depth of heat penetration and preventing overheating in certain applications can be challenging.

5. **Interference in Sensors:**

- **Signal Distortion:** Eddy currents can interfere with sensitive electronic devices and sensors, potentially distorting measurements and leading to inaccuracies.

### Conclusion

Eddy currents have a dual nature, providing significant benefits in various applications, especially in heating, testing, and braking systems. However, they also pose challenges such as energy losses and interference that need to be managed effectively. Understanding both the advantages and disadvantages of eddy currents is essential for optimizing their use in engineering and technology.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

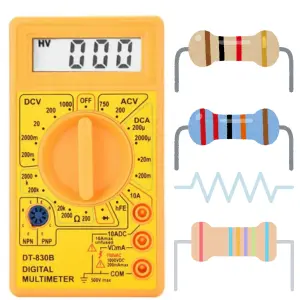

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

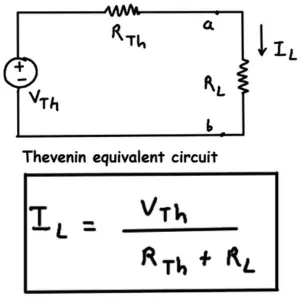

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

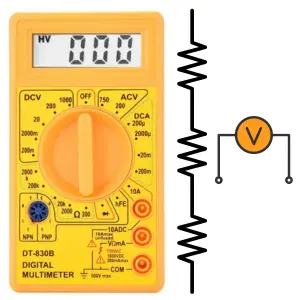

Voltmeter

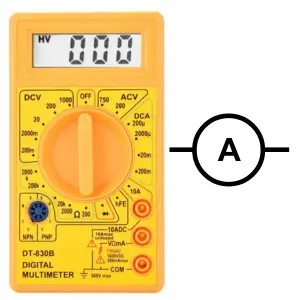

Ammeter

Induction Motor

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

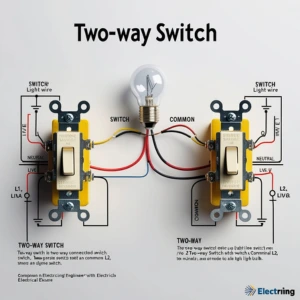

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...