2 Answers

### 1. **Magnetic Circuit Design**

- **Path for Magnetic Flux**: The air gap serves as a part of the magnetic circuit in machines. It is where the magnetic flux must travel, especially between the rotor and stator in motors and generators. The length and width of the air gap affect the overall reluctance (opposition to magnetic flux) of the magnetic circuit.

- **Reluctance and Flux Density**: A larger air gap increases the reluctance of the magnetic circuit, which can reduce the magnetic flux density in the machine. Designers aim to minimize the air gap while ensuring mechanical clearance, as a smaller air gap leads to a stronger magnetic coupling.

### 2. **Influence on Inductance and Efficiency**

- **Inductance**: The presence of an air gap influences the inductance of coils within the machine. In inductive components, a higher inductance generally leads to better energy storage capabilities. However, too large of an air gap can diminish inductance, leading to inefficiencies.

- **Efficiency**: Machines with a properly designed air gap tend to operate more efficiently. An optimal air gap minimizes losses due to magnetic saturation and hysteresis. If the air gap is too large, the machine may require more power to achieve the same output.

### 3. **Thermal Management**

- **Heat Dissipation**: The air gap also plays a role in thermal management. A well-designed air gap can aid in heat dissipation. If the air gap is too small, it may cause friction and overheating, especially in rotating machines.

- **Cooling Effects**: In some applications, the air gap can facilitate airflow, helping to cool the machine and maintain optimal operating temperatures.

### 4. **Mechanical Considerations**

- **Alignment and Tolerances**: The air gap is crucial for mechanical design, ensuring proper alignment between stationary and rotating components. Too large of a gap can lead to mechanical instability, while too small can cause wear and tear or binding.

- **Vibration and Noise**: Variability in the air gap can lead to vibrations and operational noise. Ensuring a uniform air gap helps in achieving smoother operation and reducing wear on components.

### 5. **Performance Characteristics**

- **Starting Torque**: In electric motors, the air gap size affects starting torque. A larger air gap may reduce torque, making it harder for the motor to start under load.

- **Load Characteristics**: The air gap influences how the machine performs under various loads. A well-optimized gap can help maintain consistent performance across different operating conditions.

### 6. **Electromagnetic Interference**

- **Noise and EMI**: A properly sized air gap can help in reducing electromagnetic interference (EMI) and noise generated by the machine. This is particularly important in sensitive applications where interference can disrupt other electronic devices.

### Conclusion

In summary, the air gap in electrical machines is a vital factor that impacts their magnetic properties, efficiency, thermal management, mechanical stability, performance characteristics, and electromagnetic compatibility. Designers must carefully consider the air gap during the design phase to optimize machine performance, balancing efficiency with mechanical and thermal requirements. Proper air gap design ensures that electrical machines operate reliably, efficiently, and with minimal maintenance over their lifespan.

### 1. **Magnetic Flux Path**

In electrical machines, such as transformers, motors, and generators, the air gap is the space between the stationary part (stator) and the rotating part (rotor). It is essential for the following reasons:

- **Flux Path**: The air gap forms part of the magnetic flux path. The magnetic flux generated by the stator must pass through the air gap to reach the rotor. The size and length of the air gap affect the efficiency of this flux transfer.

- **Magnetic Resistance**: The air gap introduces magnetic reluctance (analogous to electrical resistance but for magnetic circuits). The reluctance of the air gap is higher than that of the iron core, meaning that the magnetic flux prefers to flow through the iron core rather than the air gap. A larger air gap increases reluctance and reduces the efficiency of the machine.

### 2. **Influence on Performance**

The air gap directly impacts the performance and efficiency of electrical machines:

- **Inductance and Reactance**: In motors and generators, the air gap affects the inductance and reactance of the windings. A larger air gap decreases the inductance and increases the reactance, which can impact the machine's performance.

- **Torque Production**: For motors, the torque produced is inversely related to the air gap. A larger air gap reduces the magnetic coupling between the stator and rotor, leading to lower torque production. Conversely, a smaller air gap can enhance torque but might also lead to increased losses and mechanical issues.

- **Efficiency**: The efficiency of electrical machines is influenced by the size of the air gap. A smaller air gap generally leads to higher efficiency by reducing losses due to leakage flux and improving the overall magnetic coupling.

### 3. **Mechanical and Thermal Considerations**

- **Mechanical Tolerances**: The air gap must be precisely maintained to ensure proper operation. Too small a gap can lead to physical contact between the stator and rotor, causing wear and potential damage. Too large a gap reduces efficiency and performance.

- **Thermal Expansion**: During operation, electrical machines generate heat. The air gap helps in accommodating thermal expansion of the rotor and stator without causing interference or contact.

### 4. **Design Trade-offs**

- **Manufacturing Tolerance**: Achieving an optimal air gap requires balancing design and manufacturing tolerances. A precise and consistent air gap is crucial for reliable machine operation and to avoid issues like vibrations or noise.

- **Cost vs. Performance**: Reducing the air gap can enhance performance but may increase manufacturing costs and complexity. Designers must balance these factors to optimize the machine for specific applications and budget constraints.

### 5. **Noise and Vibration**

The air gap also influences noise and vibration levels in electrical machines. Variations in the air gap can lead to uneven magnetic forces, resulting in increased vibrations and noise. Proper design and maintenance help mitigate these issues.

### Summary

The air gap in electrical machines is a vital design element affecting magnetic flux distribution, performance, efficiency, and mechanical stability. It must be carefully designed and maintained to ensure optimal operation and longevity of the machine. The trade-offs between air gap size, performance, and manufacturing considerations are crucial in the design and operation of electrical machines.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

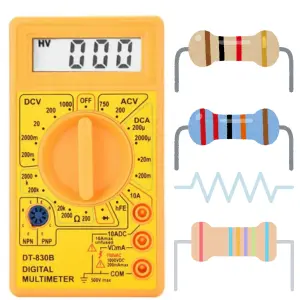

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

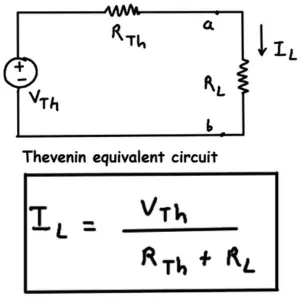

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

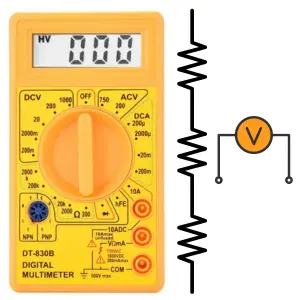

Voltmeter

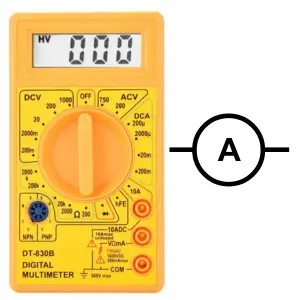

Ammeter

Induction Motor

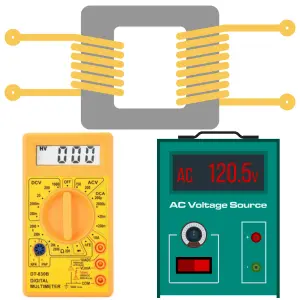

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

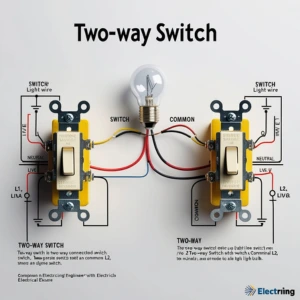

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...