2 Answers

### **Function of a Capacitor in a Start Motor Circuit**

1. **Phase Shift for Starting Torque:**

- **Single-Phase Motors:** Single-phase induction motors inherently lack starting torque because they generate a rotating magnetic field only when they are running. To overcome this, a capacitor is used to create a phase shift in the motor’s starting winding.

- **Capacitor Placement:** The capacitor is connected in series with the starting winding (often referred to as the "start winding"). This series capacitor creates a phase difference between the current flowing through the start winding and the current in the running winding (or "main winding").

2. **Creating a Rotating Magnetic Field:**

- When the motor is energized, the capacitor causes the start winding current to lead the voltage, creating a phase shift. This phase shift results in a rotating magnetic field, which is necessary to produce starting torque and get the motor up to speed.

3. **Improving Starting Performance:**

- **Starting Torque:** By enhancing the phase shift and creating a more effective rotating magnetic field, the capacitor helps generate sufficient torque to start the motor.

- **Motor Efficiency:** Once the motor reaches a certain speed, the capacitor's role in the start winding becomes less critical, and the motor’s efficiency improves as it transitions to running conditions.

4. **Capacitor Types and Operation:**

- **Start Capacitors:** These are designed for short-term use and provide a high starting torque. They are typically disconnected from the circuit once the motor reaches a certain speed, often via a centrifugal switch or relay.

- **Run Capacitors:** In contrast, run capacitors are designed for continuous operation and improve the motor’s efficiency and power factor during normal running conditions. They remain in the circuit while the motor is operating.

5. **Capacitor Disconnection:**

- In most start motor circuits, a centrifugal switch or an electronic relay disconnects the start capacitor from the circuit once the motor reaches around 70-80% of its full speed. This prevents overheating of the capacitor and ensures that the motor runs efficiently.

6. **Capacitor Ratings:**

- The capacitor used in a start motor circuit must be rated for the appropriate voltage and capacitance to handle the starting current and ensure proper motor operation. A capacitor that is too small or incorrectly rated can lead to insufficient starting torque or potential damage to the motor.

### **Summary:**

In summary, a capacitor in a start motor circuit is essential for creating the initial phase shift needed to start a single-phase induction motor. It enhances starting torque, helps establish a rotating magnetic field, and contributes to the motor’s overall performance. The capacitor is typically disconnected once the motor reaches a certain speed to avoid unnecessary wear and tear.

If you have more specific questions or need details on a particular type of motor or capacitor, feel free to ask!

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

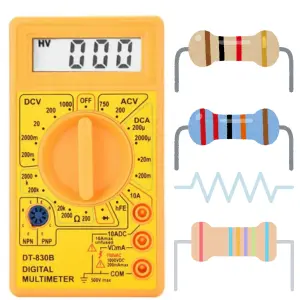

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

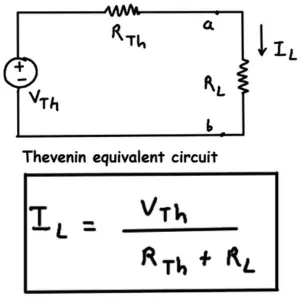

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

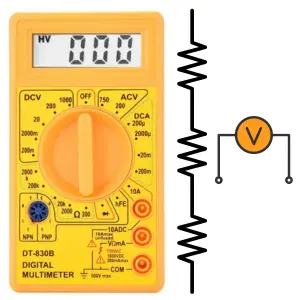

Voltmeter

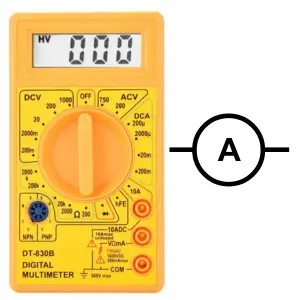

Ammeter

Induction Motor

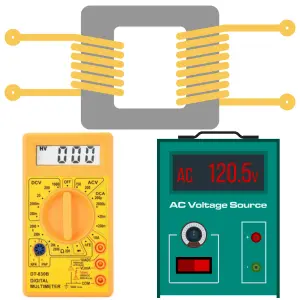

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

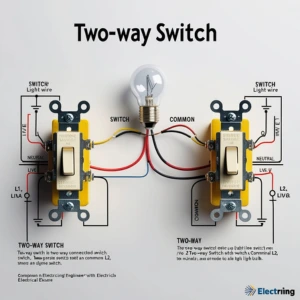

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...