2 Answers

### Key Components and Features

1. **Central Processing Unit (CPU):** The brain of the PLC, where all the processing and control decisions are made.

2. **Input/Output (I/O) Modules:** These modules connect the PLC to external devices. Input modules receive signals from sensors and switches, while output modules send control signals to actuators, lights, or other devices.

3. **Power Supply:** Provides the necessary power for the PLC to operate.

4. **Programming Device:** Used to program and configure the PLC. This can be a dedicated programming console or a computer with specialized software.

5. **Communication Interfaces:** Allow the PLC to communicate with other PLCs, computers, or network systems.

### How It Works

1. **Input:** The PLC receives data from various input devices (e.g., sensors, switches). These inputs might measure things like temperature, pressure, or position.

2. **Processing:** The PLC processes this data based on a programmed logic. This logic is defined using a programming language or graphical interface, such as Ladder Logic, Function Block Diagram, or Structured Text.

3. **Output:** After processing the input data according to the programmed logic, the PLC sends commands to output devices (e.g., motors, valves, lights) to perform specific actions.

### Uses of PLCs

PLCs are used in a wide range of applications across various industries due to their flexibility, robustness, and ease of programming. Here are some common uses:

1. **Manufacturing Automation:**

- **Assembly Lines:** PLCs control the sequencing of machines and processes on assembly lines.

- **Robotic Control:** Manage and coordinate robotic arms for tasks like welding, painting, or packaging.

2. **Process Control:**

- **Chemical Processing:** Regulate the mixing, heating, and other processes in chemical plants.

- **Oil & Gas:** Control drilling operations, manage flow rates, and monitor equipment.

3. **Building Automation:**

- **HVAC Systems:** Regulate heating, ventilation, and air conditioning systems for efficiency and comfort.

- **Lighting Control:** Manage lighting systems based on time of day, occupancy, or other criteria.

4. **Utilities Management:**

- **Water Treatment:** Control water purification processes, pump stations, and distribution systems.

- **Energy Management:** Monitor and control electrical grids, substations, and energy usage.

5. **Transportation:**

- **Traffic Lights:** Control traffic signals at intersections to manage the flow of traffic.

- **Railway Systems:** Oversee signaling and control systems for trains and track switching.

6. **Packaging and Material Handling:**

- **Conveyor Systems:** Manage the movement of goods on conveyor belts, including sorting and routing.

- **Packaging Machines:** Control the filling, sealing, and labeling of products.

### Advantages of PLCs

- **Flexibility:** Easy to reprogram for different tasks or processes.

- **Reliability:** Designed to withstand harsh industrial environments, including temperature extremes and vibrations.

- **Scalability:** Can be expanded with additional I/O modules to suit the scale of the application.

- **Cost-Effectiveness:** Reduces the need for extensive wiring and relay panels, potentially lowering installation and maintenance costs.

### Conclusion

PLCs are crucial in modern industrial and commercial automation. Their ability to handle complex control tasks, coupled with their robustness and adaptability, makes them a preferred choice for automating a wide range of processes and systems. Whether in manufacturing, process control, or building automation, PLCs help ensure that operations are efficient, reliable, and responsive to changing conditions.

### **What is a PLC?**

1. **Definition**: A PLC is a ruggedized computer used to control machinery or processes. It operates using a set of instructions to monitor inputs and control outputs based on its programmed logic. PLCs are designed to withstand harsh industrial conditions, such as extreme temperatures, electrical noise, and vibrations.

2. **Components**:

- **CPU (Central Processing Unit)**: The brain of the PLC, which processes inputs and outputs based on the program loaded into its memory.

- **Input/Output Modules**: Interface the PLC with the external devices. Input modules receive signals from sensors or switches, while output modules send signals to actuators or other devices.

- **Power Supply**: Provides the necessary power for the PLC to operate.

- **Programming Device**: A computer or handheld device used to enter and modify the PLC’s program.

3. **Programming**: PLCs are programmed using specialized languages such as Ladder Logic, Function Block Diagram, Structured Text, and Instruction List. Ladder Logic is one of the most common and is visually similar to electrical relay logic diagrams.

### **Uses of PLCs**

1. **Industrial Automation**:

- **Manufacturing**: PLCs control machinery in manufacturing plants, including conveyor systems, robotic arms, and assembly lines. They ensure that operations are performed in a precise and timely manner.

- **Process Control**: In industries such as chemical processing, PLCs manage variables like temperature, pressure, and flow rates to ensure processes run smoothly.

2. **Building Automation**:

- **HVAC Systems**: PLCs control heating, ventilation, and air conditioning systems, managing factors such as temperature, humidity, and airflow.

- **Lighting**: They can manage lighting systems, adjusting brightness and turning lights on or off based on occupancy or time of day.

3. **Transportation**:

- **Traffic Control**: PLCs manage traffic signals and control traffic flow at intersections.

- **Railways**: They handle signaling and track switching to ensure safe and efficient train operations.

4. **Utilities**:

- **Water Treatment**: PLCs control water treatment processes, including filtration, chemical dosing, and pump operations.

- **Electric Power Distribution**: They monitor and control power distribution systems, managing load balancing and fault detection.

5. **Safety Systems**:

- **Emergency Shutdowns**: PLCs can trigger emergency shutdowns of machinery or processes in case of dangerous conditions or failures.

- **Alarm Systems**: They can manage alarms and notifications to alert operators of potential issues.

### **Advantages of PLCs**

1. **Reliability**: PLCs are built to operate reliably in harsh industrial environments.

2. **Flexibility**: They can be reprogrammed and reconfigured to adapt to changes in the process or system requirements.

3. **Ease of Integration**: PLCs can integrate with various sensors, actuators, and other devices, making them versatile for different applications.

4. **Real-time Processing**: PLCs provide real-time processing, which is crucial for time-sensitive control tasks.

In summary, PLCs play a critical role in modern industrial automation, offering flexibility, reliability, and precise control for a wide range of applications. Their ability to handle complex control tasks in challenging environments makes them essential in many industries.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

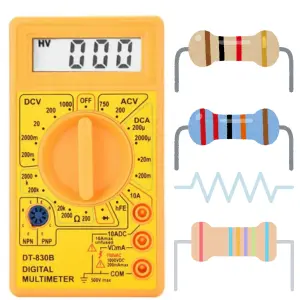

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

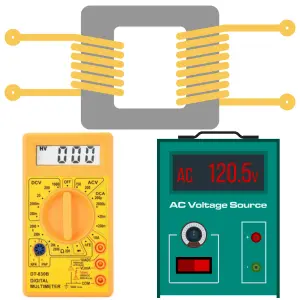

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

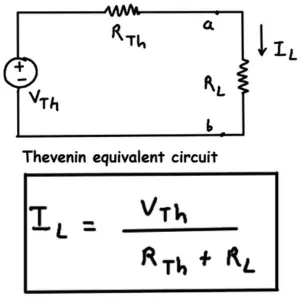

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

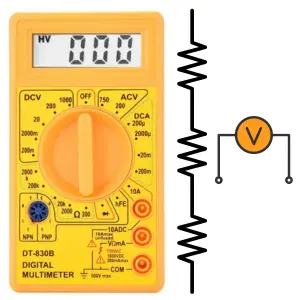

Voltmeter

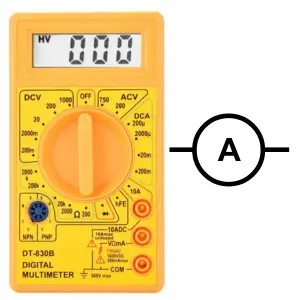

Ammeter

Induction Motor

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

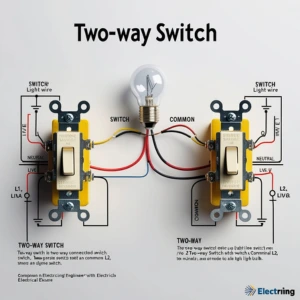

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...