2 Answers

Electric machines (motors and generators) can be categorized into two main types based on the kind of electrical power they use: **single-phase** and **three-phase**. Understanding the differences between these two types is important, especially in applications ranging from industrial machinery to household appliances.

### **1. Single-Phase Machines**

#### **Single-Phase Power:**

- **Definition**: Single-phase power is the most basic form of electrical power distribution. It uses **one alternating current (AC) waveform**.

- **Voltage**: In many countries, single-phase power is commonly delivered at 230V (in Europe, Asia) or 120V (in North America).

- **Current Flow**: The voltage and current rise and fall in a **single sine wave**. In a single-phase system, power delivery fluctuates during each cycle of the AC waveform, leading to a period of time when power is zero.

#### **Single-Phase Motors:**

- **Construction**: Single-phase motors typically have a simpler construction compared to three-phase motors. They use a single coil and require auxiliary methods like a capacitor to start the motor.

- **Applications**:

- **Household Appliances**: Fans, washing machines, refrigerators, and small pumps.

- **Small Power Loads**: Devices that require low amounts of energy (up to about 5 kW).

- **Efficiency**: Less efficient compared to three-phase motors. They are more prone to voltage fluctuations and power losses.

- **Advantages**:

- Simple design and relatively low cost.

- Easily available for residential and small commercial applications.

- Works in areas where only single-phase power is available.

- **Disadvantages**:

- Lower efficiency and power output.

- Difficult to start under load; often requires an external starting mechanism like a capacitor.

### **2. Three-Phase Machines**

#### **Three-Phase Power:**

- **Definition**: Three-phase power consists of **three alternating currents** that are evenly spaced in phase angle by **120 degrees**. This results in a constant flow of power with no periods of zero voltage.

- **Voltage**: Commonly used at 400V (in many industrial systems), 208V, or 480V.

- **Current Flow**: Since the power is delivered by three separate sine waves, power remains more constant and efficient over time.

#### **Three-Phase Motors:**

- **Construction**: Three-phase motors have **three coils** that correspond to each phase of the power supply. This design allows for a **rotating magnetic field**, which provides smoother operation.

- **Applications**:

- **Industrial Machinery**: Conveyor belts, compressors, large pumps, elevators, and air conditioning units.

- **High-Power Loads**: Suitable for equipment that requires power over 5 kW.

- **Efficiency**: More efficient and reliable than single-phase motors. They deliver a continuous flow of power, leading to higher torque and smoother operation.

- **Advantages**:

- High efficiency and reliability.

- Smoother torque output, reducing vibration and mechanical stress.

- Easier to start under load, with no need for external starting mechanisms.

- Can handle larger power loads.

- **Disadvantages**:

- More complex and expensive than single-phase motors.

- Requires three-phase power supply, which is typically found in industrial settings rather than residential areas.

### **Key Differences Between Single-Phase and Three-Phase Machines**

| **Feature** | **Single-Phase** | **Three-Phase** |

|--------------------------|-----------------------------------------|-------------------------------------------|

| **Power Delivery** | Fluctuating (zero crossing points) | Constant (no zero crossing points) |

| **Number of Phases** | 1 alternating current | 3 alternating currents |

| **Voltage** | 120V or 230V | 208V, 400V, 480V |

| **Motor Size** | Suitable for small to medium loads | Ideal for medium to large loads |

| **Efficiency** | Lower efficiency | High efficiency |

| **Power Output** | Low (less than 5 kW) | High (above 5 kW) |

| **Starting Mechanism** | Needs external start mechanism (capacitor) | Self-starting (due to rotating magnetic field) |

| **Applications** | Household appliances, small tools | Industrial machinery, heavy equipment |

| **Cost** | Cheaper and simpler | More expensive and complex |

### **Conclusion**

- **Single-phase machines** are great for small-scale applications where high power is not needed. They are commonly used in homes and light commercial environments.

- **Three-phase machines**, on the other hand, are highly efficient and designed for heavy-duty applications. They are commonly found in industrial environments where a high, continuous flow of power is required.

The choice between single-phase and three-phase systems depends largely on the application's power requirements, cost considerations, and the availability of the appropriate power supply.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

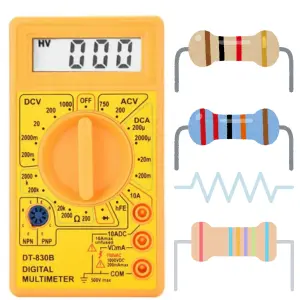

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

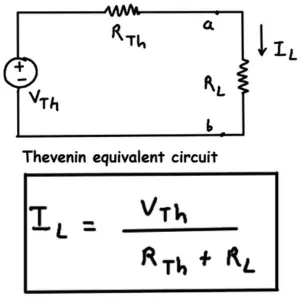

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

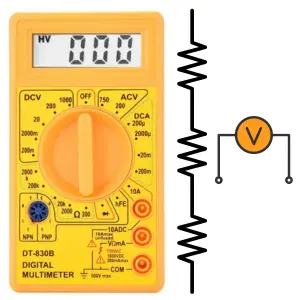

Voltmeter

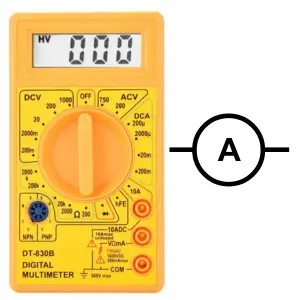

Ammeter

Induction Motor

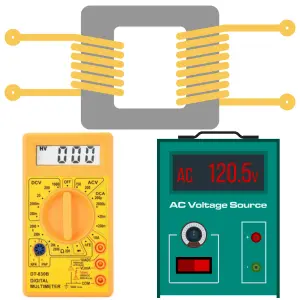

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

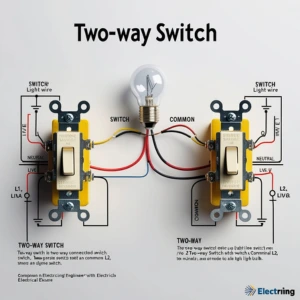

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...