2 Answers

### 1. **Medical Instrumentation**

Instrumentation amplifiers are commonly used in medical devices such as ECG (electrocardiogram) and EEG (electroencephalogram) machines. These devices need to measure tiny electrical signals from the body amidst significant noise and interference. Instrumentation amplifiers are ideal here because they can accurately amplify these small signals while filtering out noise.

### 2. **Sensor Signal Conditioning**

Many sensors, such as strain gauges, temperature sensors (like thermocouples and RTDs), and pressure sensors produce low-level output signals that need amplification. Instrumentation amplifiers provide high input impedance and differential gain, making them suitable for accurate signal conditioning in these applications.

### 3. **Data Acquisition Systems**

In data acquisition systems, instrumentation amplifiers are used to convert analog signals from sensors into a form that can be digitized by an ADC (analog-to-digital converter). The amplifier's ability to handle small signals and reject noise makes it crucial for accurate data collection.

### 4. **Industrial Process Control**

In industrial environments, instrumentation amplifiers help monitor and control processes by amplifying signals from various sensors. This includes measuring parameters like temperature, pressure, and flow rate. Their robustness and precision are essential for maintaining control and ensuring safety in industrial processes.

### 5. **Strain Measurement**

When measuring strain in materials using strain gauges, the signals produced are typically very small and require precise amplification. Instrumentation amplifiers are used to amplify these signals accurately, which is critical for structural health monitoring and material testing.

### 6. **Precision Instrumentation**

In applications where precision is critical, such as in scientific research and high-precision instrumentation, instrumentation amplifiers offer the necessary accuracy and stability. Their low offset voltage and high common-mode rejection ratio (CMRR) ensure that even minute signals are amplified correctly.

### 7. **Weighing Systems**

In weighing systems that use load cells to measure weight or force, instrumentation amplifiers amplify the small voltage changes generated by the load cells. The amplifier ensures accurate weight readings by providing precise signal conditioning.

### 8. **Audio Processing**

Although less common, instrumentation amplifiers can also be used in audio applications where high accuracy and low noise are required. They can be employed in preamplifiers to ensure that audio signals are amplified with minimal distortion.

### Key Characteristics of Instrumentation Amplifiers:

- **High Input Impedance:** They do not load the signal source, making them ideal for measuring high-impedance sources.

- **Low Output Impedance:** Ensures that the amplifier can drive the next stage effectively.

- **High Common-Mode Rejection Ratio (CMRR):** Effectively rejects unwanted noise and interference common to both input lines.

- **Precision Gain Control:** Allows for accurate amplification of small signals.

In summary, instrumentation amplifiers are essential in any situation where precise measurement and signal amplification of small differential signals are required. Their ability to reject noise and interference while maintaining accuracy makes them invaluable in medical, industrial, and scientific applications.

1. **Medical Instrumentation:**

- **Electrocardiograms (ECG)**: Amplifies the small electrical signals generated by the heart.

- **Electroencephalograms (EEG)**: Amplifies brainwave signals.

2. **Sensor Signal Amplification:**

- **Strain Gauges**: Used in load cells for measuring weight or pressure.

- **Thermocouples**: For temperature measurement, where the output voltage is very small.

- **Photodiodes**: For detecting light intensity, where the signal is usually weak.

3. **Data Acquisition Systems:**

- Used to amplify sensor signals before they are digitized for further processing.

4. **Biomedical Devices:**

- In devices like pacemakers or glucose monitors, where small biological signals need to be amplified accurately.

5. **Industrial Process Control:**

- Used in systems that monitor and control physical parameters like temperature, pressure, and flow, requiring accurate signal amplification from various sensors.

6. **Audio Preamplifiers:**

- When low-level audio signals need to be amplified with minimal noise and distortion.

The key advantages of using an instrumentation amplifier are its high input impedance, which prevents loading of the signal source, and its excellent common-mode rejection ratio (CMRR), which minimizes noise and interference.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

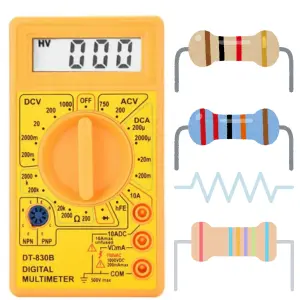

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

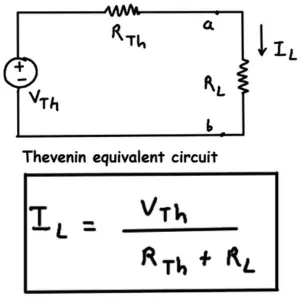

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

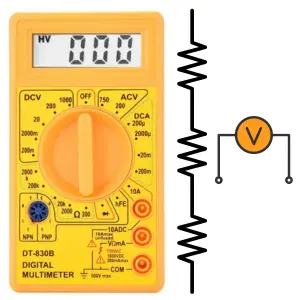

Voltmeter

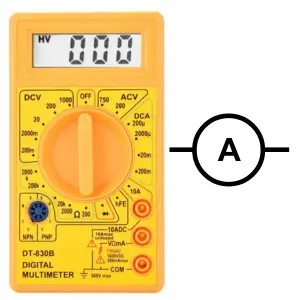

Ammeter

Induction Motor

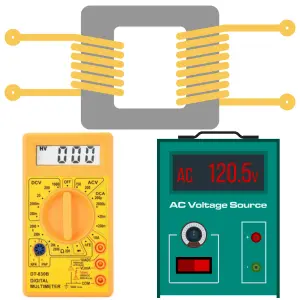

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

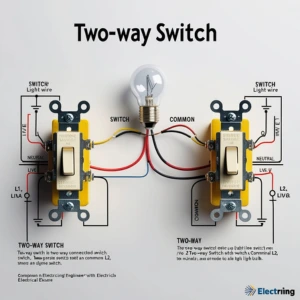

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...