2 Answers

### 1. **High Differential Gain**

Instrumentation amplifiers are designed to amplify the difference between two input signals while rejecting any signals that are common to both inputs (common-mode signals). This is essential in applications where you need to measure small signals in the presence of large noise or interference. The high differential gain ensures that only the small differential signal is amplified, providing a more accurate measurement.

### 2. **Excellent Common-Mode Rejection Ratio (CMRR)**

The CMRR of an instrumentation amplifier is very high, often in the range of 80 dB to 120 dB or more. This means it can effectively filter out common-mode noise and interference, which is critical when dealing with low-level signals or when signals are transmitted over long distances where noise pickup is a concern.

### 3. **High Input Impedance**

Instrumentation amplifiers have very high input impedance, typically in the range of megaohms (MΩ). This characteristic is important because it ensures that the amplifier does not load down the signal source. High input impedance means that the amplifier draws very little current from the signal source, preserving the integrity of the signal being measured.

### 4. **Low Output Impedance**

The low output impedance of instrumentation amplifiers ensures that they can drive subsequent stages or loads without significant signal distortion. This is especially important in systems where the amplifier's output needs to be connected to other circuitry, such as an analog-to-digital converter (ADC) or a data acquisition system.

### 5. **Adjustable Gain**

Many instrumentation amplifiers allow for easy adjustment of the gain through external resistors or digital controls. This flexibility is useful in applications where the signal amplitude needs to be scaled to match the input range of subsequent processing stages or measurement systems.

### 6. **High Stability and Accuracy**

Instrumentation amplifiers are designed to be stable and accurate across a wide range of operating conditions. This makes them suitable for precise measurement tasks, such as in medical instrumentation (e.g., ECG, EEG), industrial process control, and sensor interfacing, where accuracy is paramount.

### 7. **Noise Reduction**

The design of instrumentation amplifiers helps to minimize noise introduced by the amplifier itself. Combined with their high CMRR, this results in a cleaner output signal with reduced noise and interference, which is crucial for accurate signal processing and measurement.

### **Applications of Instrumentation Amplifiers**

1. **Medical Instrumentation:** Used in ECG and EEG machines to amplify weak biological signals while rejecting noise and interference.

2. **Industrial Process Control:** Helps in measuring signals from sensors and transducers in environments with significant electrical noise.

3. **Data Acquisition Systems:** Employed in systems where accurate and stable signal conditioning is necessary for analog-to-digital conversion and further processing.

4. **Strain Gauge Measurement:** Utilized to amplify the small voltage changes from strain gauges in structural health monitoring and material testing.

### **Conclusion**

Instrumentation amplifiers are chosen for their ability to provide precise and stable amplification of small differential signals in the presence of noise and interference. Their high input impedance, low output impedance, and excellent common-mode rejection make them ideal for applications requiring accurate signal measurement and conditioning.

### 1. **High Differential Gain**

Instrumentation amplifiers are designed to amplify the difference between two input signals while rejecting any signals that are common to both inputs (common-mode signals). This is crucial in applications where you need to measure small signals in the presence of larger, potentially noisy common-mode signals. For instance, in medical devices measuring bio-signals (like ECG or EEG), the desired signal is often very small compared to the noise, and an INA can help in accurately amplifying the small signal while ignoring the noise.

### 2. **High Input Impedance**

Instrumentation amplifiers have very high input impedance. This means they draw very little current from the signal source, which minimizes the loading effect on the circuit. This is particularly important when dealing with high-impedance sensors or sources where you want to avoid altering the signal being measured.

### 3. **Excellent Common-Mode Rejection Ratio (CMRR)**

One of the standout features of instrumentation amplifiers is their excellent common-mode rejection ratio. CMRR is a measure of how well the amplifier can reject common-mode signals. In simple terms, it quantifies the ability of the INA to ignore signals that are present on both input lines. High CMRR is essential in noisy environments to ensure that the amplifier primarily amplifies the differential signal rather than the noise that is present equally on both inputs.

### 4. **Stable Gain**

Instrumentation amplifiers provide precise and stable gain control. The gain of an INA is set by a single external resistor, making it easy to adjust and maintain. This is beneficial in applications where exact amplification is required, and where stability in gain is crucial for accurate measurements.

### 5. **Low Offset Voltage and Drift**

Instrumentation amplifiers typically have very low offset voltage and offset drift compared to other types of amplifiers. Offset voltage is the differential voltage required between the inputs to make the output zero when it should ideally be zero. Low offset is important in precision applications where even a small error can lead to significant measurement inaccuracies.

### 6. **Differential Input Protection**

INAs often include features to protect the input from high voltage spikes and transients. This makes them suitable for use in environments where input signals may be exposed to potentially damaging conditions.

### 7. **Application Versatility**

Instrumentation amplifiers are used in a wide range of applications due to their versatility. Some common uses include:

- **Medical Instrumentation:** For amplifying signals from biological sensors.

- **Industrial Sensors:** For accurate readings from pressure, temperature, or strain gauges.

- **Data Acquisition Systems:** For precise measurement of physical quantities.

- **Signal Conditioning:** To prepare signals for further processing or analog-to-digital conversion.

### **In Summary:**

Instrumentation amplifiers are chosen for their ability to amplify small differential signals in the presence of large common-mode voltages, their high input impedance, and their precise and stable gain characteristics. Their design makes them particularly well-suited for applications requiring accurate, low-noise signal amplification in challenging environments.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

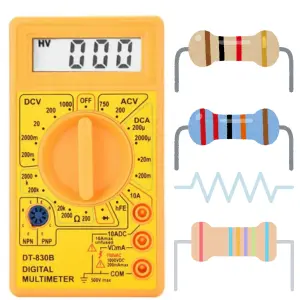

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

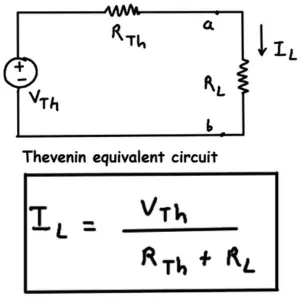

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

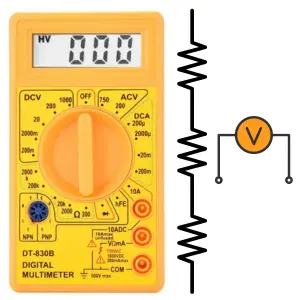

Voltmeter

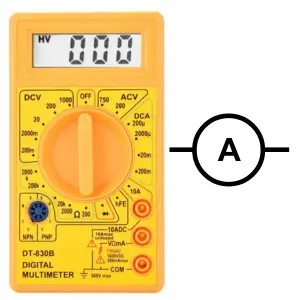

Ammeter

Induction Motor

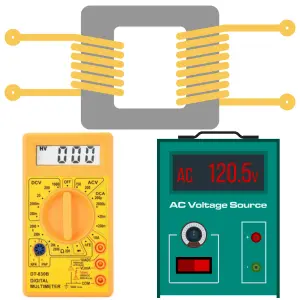

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

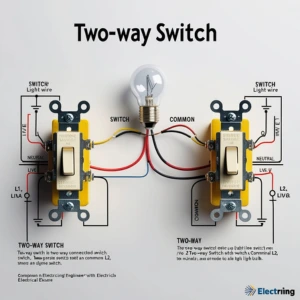

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...