2 Answers

Here's a more detailed look at PLCs and their functions:

### **1. Basic Overview**

**Programmable Logic Controller (PLC):**

- **Digital Computer:** It's a type of computer specifically engineered for control applications.

- **Industrial Environment:** PLCs are built to withstand harsh conditions like extreme temperatures, vibrations, and electrical noise.

- **Automation:** They replace traditional relay-based control systems with programmable, flexible control logic.

### **2. Key Components**

- **Input/Output (I/O) Modules:**

- **Inputs:** These receive signals from various sensors and switches, like temperature sensors or push buttons.

- **Outputs:** These send commands to actuators, motors, lights, or other devices.

- **Central Processing Unit (CPU):**

- **Processing:** The CPU processes the input data according to the program logic.

- **Memory:** It stores the control program, data, and operational state.

- **Power Supply:**

- **Electrical Power:** Provides the necessary power for the PLC to operate.

- **Programming Device:**

- **Software:** Programs and configures the PLC. This can be done using specialized software on a computer.

### **3. How PLCs Work**

- **Input Scanning:** The PLC reads the status of input devices (e.g., sensors, switches) to gather real-time data.

- **Program Execution:** It processes the data according to the pre-programmed logic or instructions. This logic is often written in languages such as Ladder Logic, Function Block Diagram, or Structured Text.

- **Output Scanning:** Based on the processed data and the logic, the PLC sends commands to output devices (e.g., motors, alarms) to perform the necessary actions.

### **4. Functions of a PLC**

- **Control:** PLCs control machinery, processes, and systems based on input data and programmed instructions. For instance, they can manage the timing of conveyor belts, control robotic arms, or regulate the flow of materials.

- **Monitoring:** They continuously monitor the status of inputs and outputs, ensuring that processes are running smoothly and efficiently.

- **Data Collection:** PLCs can gather and record operational data for analysis, which helps in improving processes and maintaining equipment.

- **Alarm and Fault Detection:** They can detect and report faults or anomalies in the system, triggering alarms or other corrective actions.

- **Interfacing:** PLCs often communicate with other systems or higher-level controls, such as SCADA (Supervisory Control and Data Acquisition) systems, for integrated process management.

### **5. Applications**

PLCs are used in various industries for tasks such as:

- **Manufacturing:** Automating assembly lines, controlling machine operations, and managing production processes.

- **Building Automation:** Regulating heating, ventilation, air conditioning (HVAC) systems, lighting, and security systems.

- **Utilities:** Managing water treatment plants, electrical grids, and other critical infrastructure.

- **Transportation:** Controlling traffic lights, railway signals, and airport baggage handling systems.

### **6. Advantages of PLCs**

- **Flexibility:** Easily reprogrammed to adapt to new processes or requirements.

- **Reliability:** Designed to operate reliably in challenging environments.

- **Scalability:** Can be used for small to complex systems, with options for expanding I/O capabilities as needed.

- **Real-Time Operation:** Provides immediate response to input changes, ensuring timely and accurate control.

In summary, PLCs are essential for modern industrial automation, providing precise and reliable control over a wide range of processes and systems. Their ability to be programmed and reprogrammed allows for significant flexibility and adaptability in various industrial applications.

### What is a PLC?

1. **Definition**: A PLC is an industrial-grade computer designed to operate reliably in harsh environments and perform real-time control and automation tasks. It’s built to handle inputs and outputs, make decisions based on programmed logic, and control machinery or processes accordingly.

2. **Components**: The main components of a PLC include:

- **Central Processing Unit (CPU)**: The brain of the PLC, where the program is executed and processing occurs.

- **Input/Output (I/O) Modules**: These handle the interaction between the PLC and external devices. Inputs could be sensors, switches, etc., while outputs could be motors, relays, lights, etc.

- **Power Supply**: Provides the necessary power to the PLC system.

- **Programming Device**: A computer or handheld device used to write and upload the PLC program.

3. **Programming**: PLCs are programmed using a specialized language, most commonly Ladder Logic (which resembles electrical relay logic diagrams), but also other languages like Function Block Diagram (FBD), Structured Text (ST), and Instruction List (IL) are used.

### Functions of a PLC

1. **Input Processing**:

- **Signal Reception**: PLCs receive input signals from various sensors or switches that monitor the state of different conditions in the process.

- **Signal Conversion**: These analog or digital signals are converted into a format that the CPU can process.

2. **Processing**:

- **Logic Execution**: The CPU processes the inputs according to the programmed logic. This can involve calculations, comparisons, and making decisions based on the input data.

- **Control Algorithms**: The PLC uses control algorithms to decide the appropriate actions. For example, it might compare the temperature of a furnace to a setpoint and decide to turn on or off a heating element.

3. **Output Control**:

- **Signal Sending**: Based on the processed logic, the PLC sends commands to output devices such as actuators, motors, or alarms.

- **Actuation**: The outputs control physical processes or machinery by activating or deactivating devices.

4. **Communication**:

- **Data Exchange**: PLCs can communicate with other PLCs or computers via industrial networks (like Ethernet, Profibus, etc.) to exchange data or synchronize operations.

- **Monitoring and Control**: Through Human-Machine Interface (HMI) systems or supervisory control and data acquisition (SCADA) systems, operators can monitor and control the PLC remotely.

5. **Data Logging and Monitoring**:

- **Historical Data**: PLCs can log data for analysis, troubleshooting, or historical record-keeping.

- **Real-Time Monitoring**: They provide real-time information about system status and performance, which can be used for diagnostics and optimization.

### Advantages of PLCs

1. **Reliability**: Designed to operate in harsh environments with high durability.

2. **Flexibility**: Easy to reprogram and adapt to different tasks or processes.

3. **Scalability**: Can be expanded with additional modules to handle more I/O points or complex tasks.

4. **Real-Time Performance**: Capable of handling real-time control tasks with minimal latency.

### Applications of PLCs

PLCs are used in a variety of applications, including:

- **Manufacturing**: Automating production lines, controlling machinery, and managing assembly processes.

- **Process Control**: Managing processes like chemical reactions, water treatment, and temperature control.

- **Building Automation**: Controlling HVAC systems, lighting, and security systems in commercial buildings.

- **Transportation**: Managing railway signaling systems, traffic lights, and conveyor systems.

In summary, PLCs are essential tools in modern industrial automation, providing robust, flexible, and reliable control for a wide range of processes and machinery.

Applied Physics

Signals and Systems

Digital Electronics

Basic Concepts

Basic Laws

Units

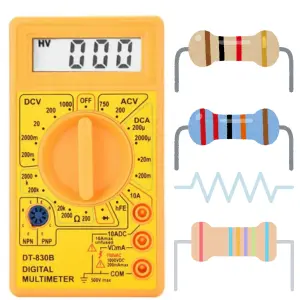

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

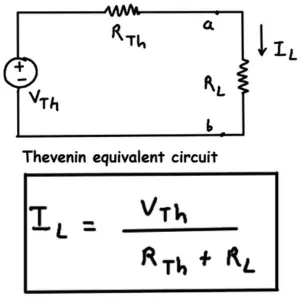

Network Theorems

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

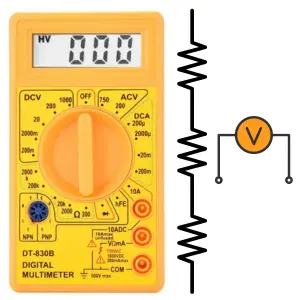

Voltmeter

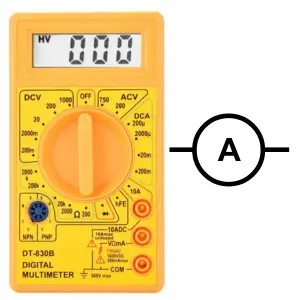

Ammeter

Induction Motor

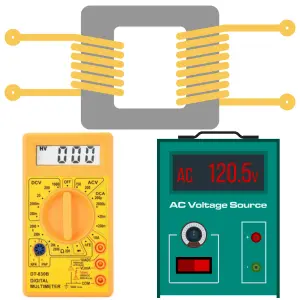

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

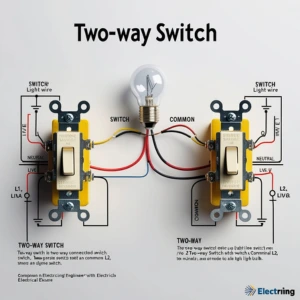

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...