2 Answers

### What is a PLC?

1. **Basic Definition**:

- A PLC is a specialized computer used in industrial environments. It monitors inputs, processes data according to pre-programmed instructions, and controls outputs to automate machinery and processes.

2. **Components of a PLC**:

- **CPU (Central Processing Unit)**: The brain of the PLC that processes the input data and executes the control program.

- **Input/Output Modules**: These modules allow the PLC to receive signals from sensors (inputs) and send signals to actuators or other devices (outputs).

- **Power Supply**: Provides the necessary power for the PLC to operate.

- **Programming Device**: This can be a computer or handheld device used to create and modify the control program.

3. **Programming Languages**:

- PLCs can be programmed using several languages, including:

- **Ladder Logic**: Mimics electrical relay logic and is widely used due to its simplicity.

- **Function Block Diagram**: Visual programming language for complex control tasks.

- **Structured Text**: A high-level language resembling Pascal.

- **Instruction List** and **Sequential Function Charts** are also options.

### How Does a PLC Work?

1. **Input Processing**:

- The PLC continuously scans its input devices (like switches, sensors, and buttons) to read their status (on/off, open/closed).

2. **Program Execution**:

- Based on the current status of the inputs and the logic programmed into it, the CPU executes the necessary control instructions.

3. **Output Control**:

- After processing the inputs and executing the program, the PLC sends signals to its output devices (like motors, lights, and valves) to perform actions accordingly.

4. **Feedback Loop**:

- The process is cyclic; the PLC continually scans inputs, executes the program, and controls outputs, allowing for real-time process control.

### Uses of PLCs

1. **Manufacturing Automation**:

- PLCs are extensively used in factories to automate machinery and manage production lines. They help improve efficiency and reduce human error.

2. **Process Control**:

- Industries such as oil and gas, chemical production, and water treatment use PLCs to control processes that require precision and reliability.

3. **Building Automation**:

- PLCs are used in building management systems to control lighting, heating, ventilation, and security systems.

4. **Transportation Systems**:

- They play a critical role in controlling systems like traffic lights, escalators, and elevators.

5. **Robotics**:

- PLCs are used in robotic arms and other automated devices, providing control over movement and operation based on various inputs.

6. **Packaging and Material Handling**:

- In packaging industries, PLCs control the movement of products through various stages of packaging, ensuring accurate timing and operation.

### Advantages of Using PLCs

1. **Flexibility**:

- PLCs can be reprogrammed for different tasks, making them adaptable to changes in production processes.

2. **Reliability**:

- Designed to withstand harsh industrial environments, PLCs offer high reliability and low maintenance.

3. **Ease of Use**:

- With graphical programming languages like Ladder Logic, PLCs can be programmed easily by technicians without extensive programming knowledge.

4. **Real-Time Monitoring**:

- PLCs allow for real-time data monitoring and troubleshooting, enabling quick responses to any issues that arise.

5. **Integration with Other Systems**:

- PLCs can be integrated with other automation systems, including SCADA (Supervisory Control and Data Acquisition) systems for comprehensive control and monitoring.

### Conclusion

In summary, PLCs are critical components in modern industrial automation, providing a reliable and flexible solution for controlling complex processes. Their ability to operate in real time, coupled with ease of programming and integration capabilities, makes them invaluable in various industries. Whether in manufacturing, process control, or building management, PLCs help enhance efficiency, safety, and productivity.

### **What is a PLC?**

1. **Definition**:

- A PLC is a ruggedized computer used for industrial automation. Unlike a personal computer, a PLC is designed to operate in harsh environments with temperature fluctuations, vibrations, and electrical noise.

2. **Components**:

- **CPU (Central Processing Unit)**: The brain of the PLC that processes all instructions and controls operations.

- **Input/Output Modules**: These modules connect the PLC to various sensors, switches, and actuators. Inputs might include signals from temperature sensors or pressure switches, while outputs control devices like motors or solenoids.

- **Power Supply**: Provides the necessary power for the PLC and its components.

- **Programming Device**: This can be a computer or a handheld device used to program the PLC.

3. **Programming**:

- PLCs are typically programmed using a specialized language known as Ladder Logic, which is designed to resemble electrical relay logic. Other programming languages used include Function Block Diagram (FBD), Structured Text (ST), and Sequential Function Chart (SFC).

### **Uses of PLCs**

1. **Manufacturing Automation**:

- PLCs control machines and processes in factories, such as assembly lines, robotic arms, and conveyor systems. They manage the sequence of operations, ensuring that each step occurs in the correct order.

2. **Process Control**:

- In industries like chemical, oil, and water treatment, PLCs monitor and control processes such as mixing, temperature regulation, and flow control. They ensure that processes remain within desired parameters.

3. **Building Automation**:

- PLCs are used in the control of HVAC systems, lighting, and security systems in commercial and residential buildings. They help manage energy efficiency and maintain comfortable environments.

4. **Transportation Systems**:

- PLCs control and monitor transportation systems, including traffic lights, railway signaling, and even airport baggage handling systems. They ensure the smooth operation and safety of these systems.

5. **Utilities**:

- In utilities such as water and wastewater treatment plants, PLCs control pumps, valves, and other equipment to manage the treatment process and ensure regulatory compliance.

6. **Energy Management**:

- PLCs help manage and optimize the operation of power generation and distribution systems, including renewable energy sources and smart grids.

### **Advantages of Using PLCs**

1. **Flexibility**:

- PLCs can be reprogrammed to accommodate changes in processes or system requirements, making them versatile and adaptable.

2. **Reliability**:

- Designed to operate in harsh environments, PLCs are highly reliable and capable of continuous operation without frequent maintenance.

3. **Real-Time Operation**:

- PLCs can process inputs and outputs in real time, providing immediate responses to changes in the system.

4. **Ease of Troubleshooting**:

- PLCs offer diagnostic and troubleshooting capabilities, allowing operators to quickly identify and resolve issues.

5. **Scalability**:

- PLC systems can be easily expanded by adding more modules or integrating with other control systems.

In summary, PLCs are essential components in modern industrial automation and control systems. They provide reliable, flexible, and real-time control over a wide range of applications, enhancing efficiency and productivity in various sectors.

Applied Physics

Signals and Systems

Digital Electronics

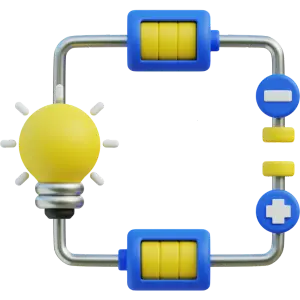

Basic Concepts

Basic Laws

Units

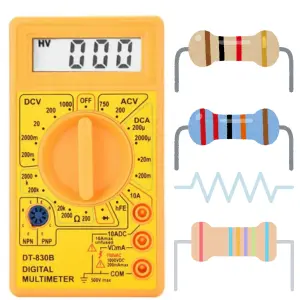

Ohmic Resistors

Capacitors and Inductors

RC Circuit

First-Order Circuits

Second-Order Circuits

Principles Of Circuit Analysis

Sinusoids and Phasors

AC Steady-State Analysis

Single Phase A.C. Circuits

Three-Phase Circuits

Resonance In Series And Parallel Circuits

Network Theorems

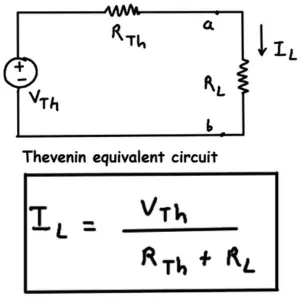

Thevenin's Theorem

Two-port Networks

Digital Electronics

Oscilloscope

Ohmmeter

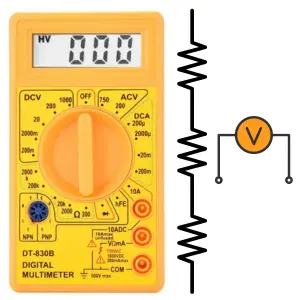

Voltmeter

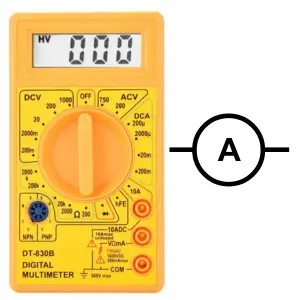

Ammeter

Induction Motor

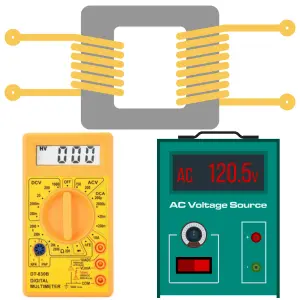

Transformer

Operational Amplifiers

Components

Symbols

Formulas

EE Notes

EE Dictionary

MCQ Quiz

Interview Q&A

Power Electronics Book

Advanced Calculator

Basic Calculator

Simulator

Videos

Q&A

Capacitance Meter

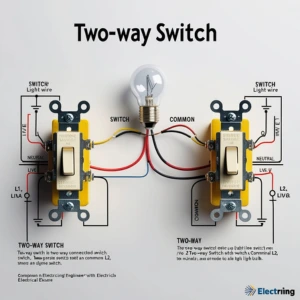

Two Way Switch

Electrical Machines

Power Electronics

Electrical Drives & Their Control

Electrical Safety & Standards

Basics of Electronics Engineering

Electromagnetic Fields

Electrical Machines

More Items Coming Soon...